Fuel container

In today's world, Fuel container continues to be a topic of great relevance and interest to a large sector of the population. Over time, Fuel container has managed to remain at the center of attention of academics, professionals and amateurs, demonstrating its importance and impact in different areas of society. Throughout history, Fuel container has been the subject of numerous studies, debates and reflections, which has contributed to enriching knowledge on this topic. In this article, we will explore some key aspects related to Fuel container, with the aim of delving into its meaning, its evolution and its relevance today.

A fuel container is a container such as a steel can, bottle, drum, etc. for transporting, storing, and dispensing various fuels.

Construction

A wide variety of container types and constructions are used for fuels. Each has its own engineering challenges.

The jerrycan is a robust liquid container originally made from pressed steel. It was designed in Germany in the 1930s for military use to hold 20 litres (4.4 imp gal; 5.3 US gal) of fuel. Three handles allow for two people carrying a full can or one person handling an empty can. The basic design is still in use today although construction is often of high density polyethylene.[1]

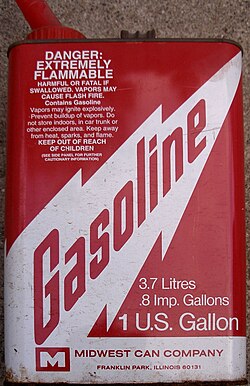

Portable plastic gasoline containers are commercially available and are in common use.[2] These are usually blow molded polyethylene or other polymers compatible with the designated fuel. It has been found that the use of flame arresters reduces the chance of fire or explosion of gasoline.[3][4] Child resistant caps or closures are required in some regions or jurisdictions.[5]

A drum (also called a barrel) is a cylindrical container used for shipping fuels. A typical drum has a nominal capacity of 200 litres (55 US or 44 imp gal). Drums are usually made of steel, but plastic drums are used for some liquids. Fuel drums need have the appropriate certification for shipment of dangerous goods: Flammable liquids, etc. Steel drums are suited for reconditioning for multiple uses.

Grounding

Pouring of a flammable liquid has the potential of generating static electricity. Having the fuel container on the ground or having a grounding strap helps reduce the risk of sparks. In particular, loading a fuel container on a flatbed truck or vehicle can be dangerous because it is insulated.[6]

Regulations

Shipments of flammable or explosive liquids are highly regulated. Based on the UN Recommendations on the Transport of Dangerous Goods model regulations, each country has coordinated design and performance requirements for shipment. For example, in the US, the Department of Transportation has jurisdiction and published requirements in Title 49 of the Code of Federal Regulations.[7]

The applicable regulation depends on the flash point of the fuel, quantity being shipped, mode of transit, etc.

Examples

-

1930s vintage 2-gallon petrol can

-

WW2 4 imperial gallon (18L) can or Flimsy

-

WWII Jerrycan

-

4L can of kerosene

-

Charcoal lighter fluid in a plastic Squeeze bottle

-

Drums of aviation fuel 1945

-

lighter fluid can

-

Intermodal tank container

-

Fuel bladder in Antarctica

-

A typical gasoline container.

-

Gas to liquids fuel containers

-

A 20 lb (9.1 kg) steel propane cylinder.

-

Camp stove with can of butane fuel

See also

- Bottled gas

- Drum pump

- Flammability limit

- Flame arrester

- Fuel tank

- Gas cylinder

- Nuclear flask

- Pressure vessel

- Tank car

- Tank container

- Tank truck

References

- ^ CID 59592, COMMERCIAL ITEM DESCRIPTION CAN, FUEL, MILITARY: 20-LITER CAPACITY, US General Services Administration, January 2009, retrieved 14 March 2020

- ^ ASTM F852 / F852M, Standard Specification for Portable Gasoline, Kerosene, and Diesel Containers for Consumer Use

- ^ Stevick, Glen (2011). "Failure Analysis and Prevention of Fires and Explosions with Plastic Gasoline Containers". Journal of Failure Analysis and Prevention. 75 (11): 455–465. doi:10.1007/s11668-011-9462-z.

A flame arrester works by removing heat from a flame and keeping the temperature of the fuel on the other side of the arrester below its ignition point. The flame arrester mesh breaks the flame into many flamelets, and the heat of these flamelets is transferred to the walls of the mesh

(The link is to the abstract only: A free full-text link is on Google Scholar.) - ^ ASTM F3326 Standard Specification for Flame Mitigation Devices on Portable Fuel Containers

- ^ ASTM F2517-17 Standard Specification for Determination of Child Resistance of Portable Fuel Containers for Consumer Use

- ^ Fire Hazard from Filling Portable Gas Cans in Pickup Trucks and Cars, DHHS (NIOSH) Publication No. 98-111, 1998, retrieved 25 July 2020

- ^ "How to Comply with Federal Hazardous Materials Regulations". United States Department of Transportation. Archived from the original on 12 March 2014. Retrieved 14 March 2020.

- ASTM F3063, Standard Specification for Aircraft Fuel Storage and Delivery

- Yam, K. L., Encyclopedia of Packaging Technology, John Wiley & Sons, 2009, ISBN 978-0-470-08704-6

External links

- Jerry Cans: The True Secret Weapon of WWII—Calum on YouTube